产品

Industry Machines

▶Type: Turning-milling compound Lathe

▶Max. Processing Diameter: Φ7mm

▶Optional working with CNC Feeder

Learn more

▶Type: Multiple Spindle Cutter Lathe / Turning-milling compound Lathe / Slant bed lathe

▶Max. Processing Diameter: Φ20mm

▶Optional working with CNC Feeder

Learn more

▶Type: Slant bed lathe

▶Max. Processing Diameter: Φ25mm

▶Optional working with CNC Feeder

Learn more

▶Type: Turning-milling compound Lathe / Slant bed lathe

▶Max. Processing Diameter: Φ32mm

▶Optional working with CNC Feeder

Learn more

▶Fully automatic pipe bender, with PC control system (more advanced than PLC), two servo for rotary, feeding

▶Electric control Bending arm (C-axis), Hydraulic Clamping die and Pressure die.

▶Servo Motor control Carriage (Y-axis) & Collet (B-axis)

▶Water-cooling system

▶Foot pedal with emergency stop

▶Touch screen, different bending degree prefabricate, dialogue operation, can choose manual/semi-automatic/full automatic operation, Multi axes working simultaneously.

▶Backup of programs by USB / disk storage/ Internet. Management and storage of bend data and tools is done in standard text files on the hard disk of the control PC. In case of requirement it is also possible to integrate the PC into bending machine. Therefore an Ethernet adapter is included. The number of tools and products are practically unlimited. Products and tool files can easily be edited (also on a separate PC) and printed out.

▶ PC assorted with touch screen display, capable of 3D bending simulation, 3D preview and collision prevention.

▶Security code for the protection the data setting and selected operation features.

▶All the parts of hydraulic system, control system, driver system and display system are imported from famous brand, with high accuracy, high efficient, suitable for mass production.

▶Max bending radius: R60 / R80 / R150

▶Min bending radius: R10 / R15

▶Max O.D × thickness:

Copper&Aluminum: Φ15×1.5mm / Φ20×2.0mm / Φ32×3.0mm / Φ38×3.0mm

Mild Steel: Φ26×2.5mm / Φ32×2.5mm

Learn more

Tube Hole Punching & Flanging Machine

▶Punching Holes & Flanging one time

▶Number of axes: Single or Multi-axis

▶Tube Diameter: Min. ∅16mm - Max. ∅50mm / ∅80mm / ∅120mm (Copper)

▶Tube Length: Max.3000mm

▶Touching Screen settings, NC control system, precise servo motor positioning, module storage memory function.

▶ Hydraulic forming and Servo feeding

▶Optional Loading / Unloaing system

Learn more

C Frame Fin Press Machine Line

▶ Pressure Capacity: 45Tons / 63Tons / 80Tons

▶ With motorized adjustment for die-setting height

▶ With hydraulic overload protector

▶ With moving junk box

▶ With 1P→2Pfunction

▶ With lubrication unit, to prolong die’s life

▶ With manual oil lubrication pump

▶With Uncoiler

▶With Oil tank and conducted coil-feeding

▶ With Vacuum sucker and collection unit

▶ Operation method: moving operation panel

▶ Fin Pattern: The buyer supply the drawing

Learn more

▶Bending Layers: 1 layer - 3 layers

▶Bending Angle: 0° - 105° (Adjustable)

▶Max. width : 800mm / 1200mm (Lift arm type)

▶Max. width : 1500mm (Gantry type)

▶Inner Radius Negotiable

Learn more

▶Bending Layers: 1 layer - 3 layers

▶Bending Angle: 0° - 105° (Adjustable)

▶Max. width : 800mm / 1200mm (Lift arm type)

▶Max. width : 1500mm (Gantry type)

▶Inner Radius Negotiable

Learn more

▶Maximum Welding Height: 1250mm / 1500mm / 2000mm / 2500mm

▶Burning gas: Liquefied gas and Natural gas

▶Auxiliary gas: Compressed air...

▶Burner: 4-row, each row have 20 welding nozzles

▶Manual adjusting combustion flame

Learn more

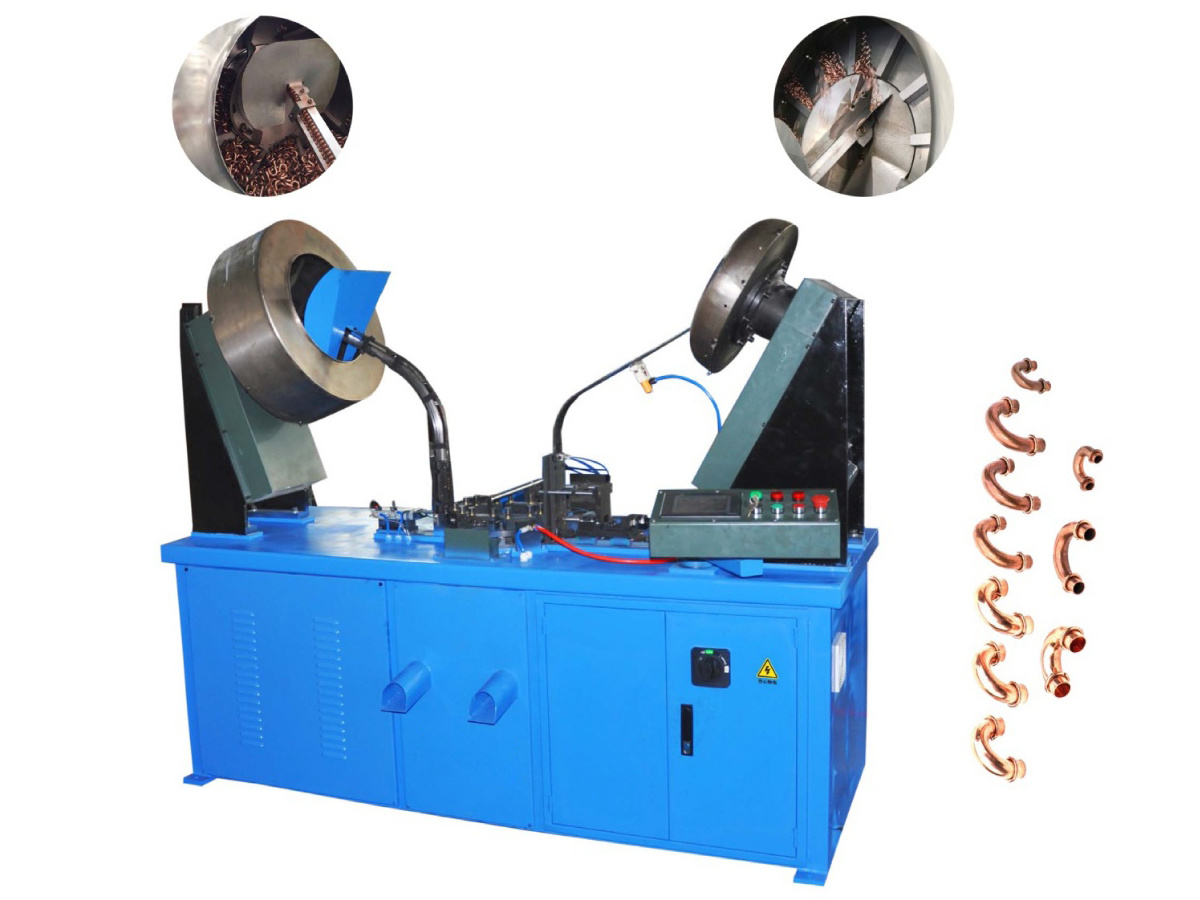

Multi Station Tube Ring Machine

▶Tube diameter: ∅5mm - ∅12.7mm

▶Elbow pipe pitch distance: 15.45mm - 31.75mm

▶60 times/min

Learn more

▶Tube Diameter: ∅5mm - ∅22mm

▶Bending Tubes: one time 2pcs / one time 3pcs / one time 5pcs

▶Speed: 8 times/min - 10 times/min

Learn more

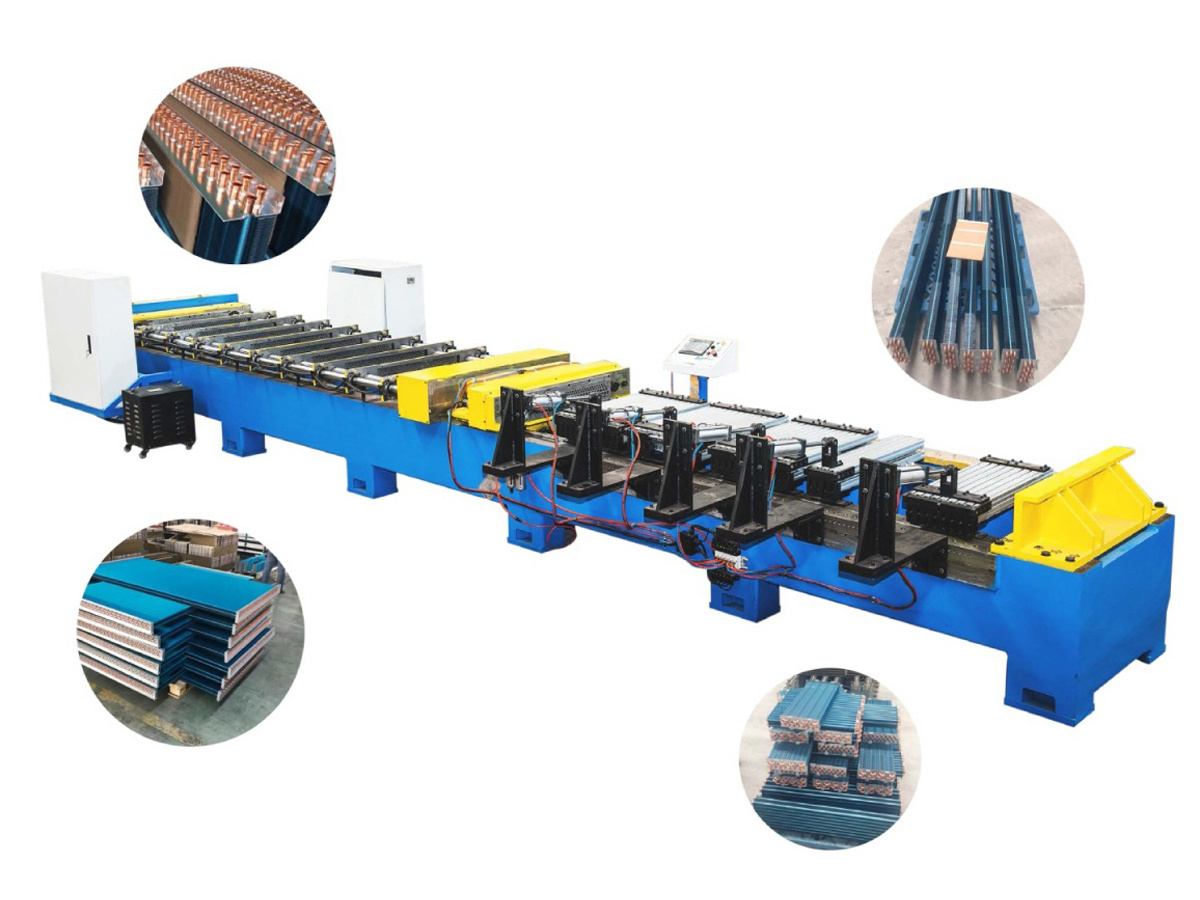

CNC Horizontal Expander (Rotating Table)

▶Workpiece Length: 2000mm / 2500mm / 3000mm / 3500mm / 4000mm

▶Fast Forward Expanding Speed: 4m/min (Adjustable)

▶Slow Speed (2nd flaring and flanging): 0.4m/min (Adjustable)

▶Return Speed (2nd flaring and flanging): 5m/min (Adjustable)

▶Air Pressure: 0.5Mpa - 0.8Mpa

▶Power: 10KW - 18KW

Learn more

▶Workpiece Length: 2000mm / 2500mm / 3000mm / 3500mm / 4000mm

▶Fast Forward Expanding Speed: 4m/min (Adjustable)

▶Slow Speed (2nd flaring and flanging): 0.4m/min (Adjustable)

▶Return Speed (2nd flaring and flanging): 5m/min (Adjustable)

▶Air Pressure: 0.5Mpa - 0.8Mpa

▶Power: 10KW - 18KW

Learn more

▶Workpiece Length: 1600mm / 2000mm / 2500mm / 3000mm

▶With 84° Rotation Worktable

▶With Oil Cylinder Insert

Learn more

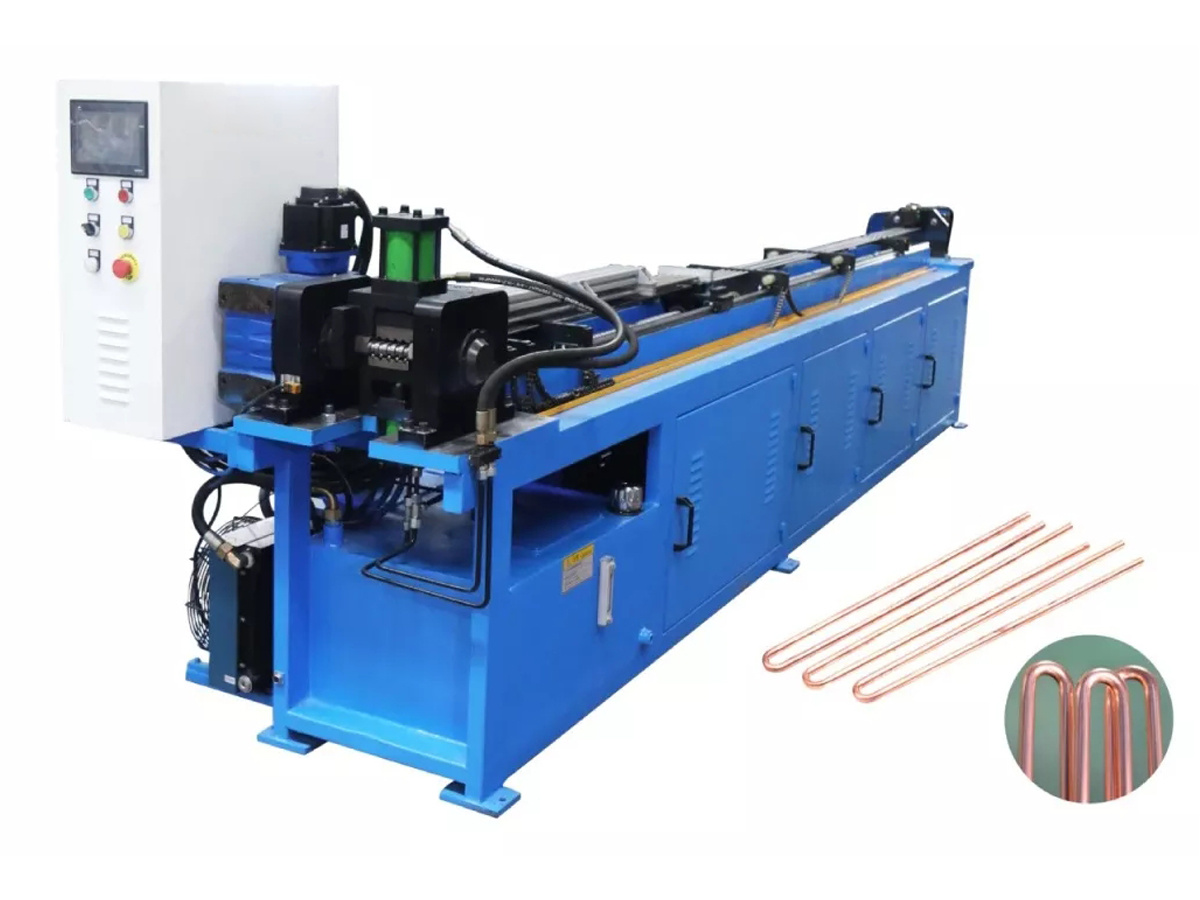

Semi-Automatic Long U Pipe Bender

▶1-5 pcs per time

▶Length: Min 200mm - Max 1250mm / 1650mm / 2150mm / 2650mm / 3150mm / 4000mm

▶Servo Motor Control Bending / Positioning discharge

▶Copper tube diameter: ∅7mm - ∅16mm

▶Bending Center: 16mm - 60mm

Learn more

Fully Automatic Long U Pipe Bender

▶1-8 pcs per time

▶Length: 200mm - Max 1250mm / 1650mm / 2150mm / 2650mm / 3150mm / 5000mm

▶Servo Motor Control Bending / Positioning discharge / Stroke

▶Copper tube diameter: ∅5mm - ∅16mm

▶Bending Center: 16mm - 60mm

Learn more

288 Qinhuai Dadao, Lishui District, Jiangsu Province, China

288 Qinhuai Dadao, Lishui District, Jiangsu Province, China 025-5720 8575

025-5720 8575 sales@bhtie.com

sales@bhtie.com